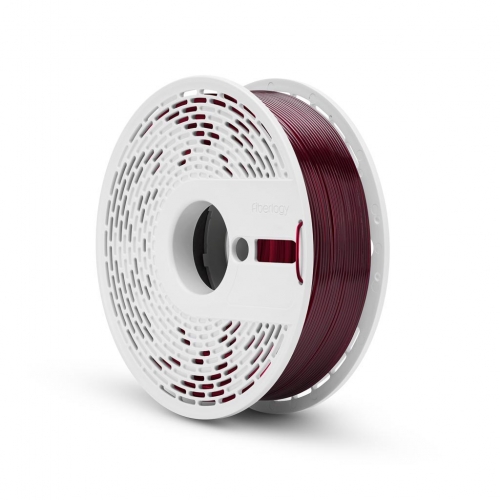

Fiberlogy EASY ABS 1.75 mm Burgundy Transparent 750 g

EABS-BURGUNDYTR-175-075

Brand: Fiberlogy, Poland

Fiberlogy EASY ABS is a filament combining the strength of ABS with ease of printing. It doesn't require an enclosed chamber, allows for creating transparent glossy items, and is easily smoothed with acetone.

- Strength: High | Stiffness: High

- Printing Difficulty: Low (for ABS)

- Printing Temperature: 235°C - 255°C

- Bed Temperature: 90°C - 110°C

- High impact resistance

- Possibility of obtaining transparent prints

- Easily smoothed with acetone vapor

- NET Weight: 750 g

Fiberlogy EASY ABS Filament Description for 3D Printers

Discover easy printing of durable parts with Fiberlogy EASY ABS! This 1.75 mm diameter, 750 g filament, presented by 3D4U, is a step towards users who want the benefits of ABS without needing specialized 3D printers.

The main feature of EASY ABS is a significantly simplified printing process compared to traditional ABS. It is less prone to shrinkage and warping, allowing printing even without an enclosed chamber (although it can still be beneficial for maximum quality). This makes durable and long-lasting ABS accessible to a wider range of users and printers.

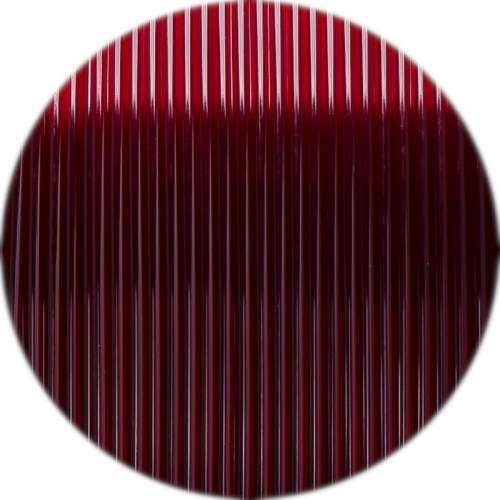

Additionally, EASY ABS offers the unique possibility of creating transparent prints with a high degree of gloss. After treating the model with acetone vapor, the surface becomes smooth and uniform, perfectly mimicking glass. This opens up new horizons for designing lamps, lampshades, decorative elements, and other items where aesthetics and transparency are important.

Despite its ease of printing, EASY ABS retains the high strength and impact resistance characteristic of ABS, as well as good chemical resistance and heat resistance up to approximately 90°C. The material also has a lower density (1.09 g/cm³), allowing for the creation of strong yet lightweight models.

3D4U is an official distributor of the Polish brand Fiberlogy.

We offer a wide range of filament for 3D printers, provide professional consultations, and guarantee the authenticity of all Fiberlogy products.

Fiberlogy EASY ABS Filament Properties

Fiberlogy EASY ABS stands out from other materials thanks to its unique set of characteristics:

- Ease of Printing: Significantly easier to work with than standard ABS, less shrinkage.

- No Enclosed Chamber Required: Allows printing on a wider range of FDM printers.

- High Impact Resistance: Retains the strength and durability inherent to ABS.

- Transparency Option: Available in transparent versions with high gloss.

- Chemical Post-Processing: Easily smoothed with acetone vapor for a perfectly smooth, glass-like surface.

- Good Heat Resistance: Withstands temperatures up to approximately 90°C.

- Chemical Resistance: Resistant to many chemicals.

- Low Density: Allows for the creation of lightweight and durable items.

Aesthetics and Strength: EASY ABS perfectly combines the ability to create beautiful, glossy, or transparent objects with the mechanical reliability of ABS.

Examples of Items Printed with EASY ABS

Vase demonstrating the transparency and gloss of EASY ABS

Example print of a transparent cup using EASY ABS

Close-up showing the surface smoothness of EASY ABS

Complex model demonstrating the printing capabilities of EASY ABS

Applications of EASY ABS

The unique combination of properties in EASY ABS opens up wide possibilities for its use:

- Home & Decor: Parts and housings for household appliances, decorative elements, lampshades, diffusers, vases where transparency or gloss is important.

- Toys: Elements mimicking glass, decorations, lightweight bodies for RC models.

- Electronics: Housings for controllers, covers for LED strips and indicators.

- Prototyping: Creating functional prototypes, small-batch production of parts requiring ABS strength and good appearance.

This 3D printing material allows for the easy creation of both functional and aesthetically pleasing items.

Fiberlogy EASY ABS Print Settings

To achieve the best results when printing with Fiberlogy EASY ABS filament, it is recommended to adhere to the following settings. Remember that optimal parameters may vary for your specific 3D printer.

| Parameter | Value |

|---|---|

| Nozzle Temperature | 235-255°C |

| Build Plate Temperature | 90-110°C |

| Enclosed Chamber | Not required (but recommended for stability) |

| Cooling Fan | 0-10% |

| Flow Rate | 95-105% |

| Print Speed | < 100 mm/s |

| Build Surface | Glass + PVA glue or hairspray, adhesive coatings |

| Retraction (direct) | 2-3 mm |

| Retraction (bowden) | 3-5 mm |

| Retraction Speed | 20-45 mm/s |

| Drying Conditions | 60°C / 4h |

Note: When printing without an enclosed chamber, try to avoid drafts and sharp temperature changes around the printer to minimize the risk of warping. For adhesion to glass, the manufacturer recommends using PVA glue or hairspray.

EASY ABS Technical Specifications

| Parameter | Value | Test Method |

|---|---|---|

| Diameter | 1.75 mm | - |

| Diameter Tolerance | ± 0.02 mm | - |

| Average Ovality | + 0.01 mm | - |

| Net Weight | 750 g | - |

| Density | 1.09 g/cm³ | ISO 1183 |

| Tensile Strength (at yield) | 47 MPa | ISO 527 |

| Tensile Modulus | 2000 MPa | ISO 527 |

| Elongation at Break | 30% | ISO 527 |

| Flexural Strength | 70 MPa | ISO 178 |

| Flexural Modulus | 2050 MPa | ISO 178 |

| Izod Impact Strength (notched at 23°C) | 15 kJ/m² | ISO 180 |

| Heat Deflection Temperature (HDT, 0.45 MPa) | 90°C | ISO 75 |

| Heat Deflection Temperature (HDT, 1.8 MPa) | 81°C | ISO 75 |

| Vicat Softening Temperature | 92°C | ISO 306 |

| Glass Transition Temperature (Tg) | 105°C | DSC |

Tips for 3D Printing with Fiberlogy EASY ABS

To get the most out of Fiberlogy EASY ABS, use these tips:

- Temperature Settings: Adhere to the recommended nozzle (235-255°C) and build plate (90-110°C) temperatures. A stable build plate temperature is crucial for adhesion.

- Build Plate Adhesion: Use PVA glue or hairspray on glass, or other adhesive solutions recommended for ABS. Build plate cleanliness is also important.

- Minimize Drafts: If printing without an enclosure, ensure the printer is not in a drafty area. Temporary shields can be used.

- Cooling Fan: Use minimal cooling (0-10%), similar to regular ABS, for better layer bonding.

- Acetone Smoothing: To achieve a glass-like surface on transparent models, use acetone vapor treatment. Experiment with exposure time to get the desired effect. Perform the procedure safely!

- Filament Drying: EASY ABS, like other ABS-based filaments, can absorb moisture. Drying at 60°C for 4 hours will improve print quality.

Transparency Tip: For maximum transparency, print with a layer height close to the nozzle diameter (e.g., 0.3 mm for a 0.4 mm nozzle) and use 100% infill or spiral vase mode. Acetone treatment significantly enhances transparency.

Comparison of EASY ABS with Other Fiberlogy Materials

EASY ABS occupies a unique niche due to its combination of properties:

| Material | Key Advantages | Key Disadvantages | When to Choose EASY ABS |

|---|---|---|---|

| Fiberlogy EASY ABS | Ease of printing (for ABS), no enclosure needed, transparency, strength, acetone smoothing | Lower heat resistance than ABS PLUS, odor during printing, low UV resistance | When ABS strength is needed, but with easier printing and/or the option for transparent/glossy parts |

| Fiberlogy ABS | High strength, impact resistance, heat resistance, machinability | Difficult to print (shrinkage, odor, enclosure needed), low UV resistance | For maximum strength and heat resistance, if printing conditions allow |

| Fiberlogy ABS PLUS | Increased strength, reduced shrinkage, easier to print than ABS | Still requires high temperatures, odor, low UV resistance | For strong parts with simplified printing, when transparency is not needed |

| Fiberlogy Easy PET-G | Strength, chemical resistance, low shrinkage, ease of printing | Moderate heat resistance, not acetone-smoothable, harder to achieve transparency | As an alternative for strong parts if acetone smoothing or high ABS heat resistance is not required |

EASY ABS is a compromise between ease of printing, strength, and unique aesthetic possibilities (transparency, gloss).

Why Choose Fiberlogy EASY ABS

Fiberlogy EASY ABS is an excellent choice if you are looking for:

- Accessible ABS: The ability to print with a strong material without necessarily needing an enclosed chamber.

- Transparency and Gloss: The unique option to create transparent or perfectly smooth glossy items after acetone treatment.

- Strength and Durability: Retention of high impact resistance and sufficient heat resistance for many applications.

- Versatility: Suitable for printing both functional and decorative objects.

- Fiberlogy Quality: Parameter stability and high-quality raw materials.

- 3D4U Support: Guarantee of authenticity and assistance in selection from an official distributor.

Try the easy path to strong and beautiful ABS prints with Fiberlogy EASY ABS!

How to Order Fiberlogy EASY ABS

Ordering Fiberlogy EASY ABS filament is quick and convenient through the 3D4U online store:

- Select the desired color and diameter (1.75 mm).

- Ensure the weight (750 g) meets your needs.

- Add the product to your cart.

- Proceed to checkout and enter the necessary shipping information.

- Choose your preferred payment and shipping method.

- Confirm your order.

If you have any questions about the properties of Fiberlogy EASY ABS, printing specifics, or the ordering process, our consultants are ready to help.

Start printing easily and beautifully with Fiberlogy EASY ABS from 3D4U!

FAQ (Frequently Asked Questions) about Fiberlogy EASY ABS

The main advantage is ease of printing. EASY ABS has significantly less shrinkage, allowing it to be printed without necessarily using an enclosed 3D printer chamber. This reduces the risk of warping and layer separation, making ABS printing accessible to a wider range of users and equipment.

Transparent versions of EASY ABS can achieve a good degree of transparency, especially after acetone vapor treatment. Without treatment, the surface will be glossy but with visible layer lines, reducing transparency. After acetone smoothing, the surface becomes smooth, mimicking glass or cast plastic. The degree of transparency also depends on the model's wall thickness and print settings (e.g., printing in vase mode yields better results).

According to the technical data sheet (TDS), the mechanical properties of EASY ABS (tensile strength, flexural strength, modulus) are very close to standard Fiberlogy ABS. The Izod impact strength of EASY ABS is slightly lower (15 kJ/m² vs. 30 kJ/m² for standard ABS) but remains high, providing good impact resistance. Thus, there is a slight reduction in impact strength in exchange for ease of printing and transparency.

The manufacturer recommends using PVA glue or hairspray when printing on a glass build plate. Standard adhesive coatings and glues designed for ABS, such as 3DLAC or similar products, also work well. It is important to ensure the build plate surface is clean and adequately heated to 90-110°C.

Yes, it is recommended. Like any ABS-based material, EASY ABS can absorb moisture from the air, which negatively affects print quality (bubbles, poor layer adhesion, stringing). It is recommended to dry the filament at 60°C for 4 hours before use, especially if the spool has been opened and stored for some time.

| Manufacturer | Fiberlogy |

|---|---|

| Printing technology | FDM/FFF |

| Material type | ABS |

| Printing temperature, ℃ | 235-255 |

| Platform temperature, ℃ | 90-110 |

| Filament diameter, mm | 1.75 |

| Allowable deviation, mm | ±0.02 |

| Density, kg/m³ | 1.09 |

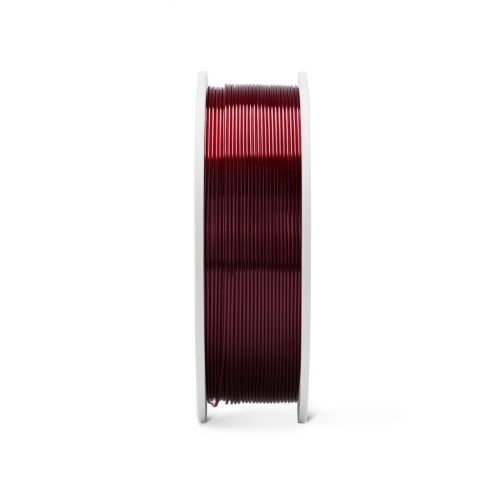

| Color | Burgundy Red |

| Surface Finish / Effect | Transparent |

| Filler / Additives | No Additives |

| Heat Resistance | High (85-110°C) |

| Special Properties | Rigid |

| Spool Format | Standard Spool |

| Length, m | 285 |

| Weight, kg | 0.750 |

| Country | Poland |

| Condition | New |

No reviews for the product