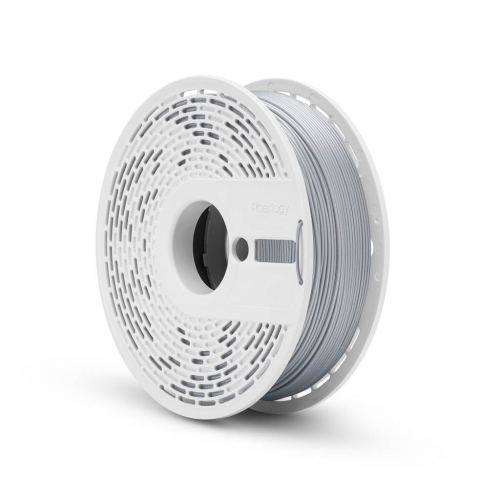

Fiberlogy Nylon PA12 1.75 mm Inox 750 g

PA12-INOX-175-075

Brand: Fiberlogy, Poland

Fiberlogy Nylon PA12 is a high-strength and flexible nylon filament resistant to high temperatures, chemicals, and abrasion. Ideal for functional engineering parts.

- Strength: High | Flexibility: Very High (>200% elongation)

- Printing Difficulty: High (Requires drying and enclosed chamber)

- Print Temperature: 255°C - 270°C

- Bed Temperature: 90°C - 110°C

- Excellent chemical resistance (oils, fuels, solvents)

- High heat resistance (up to 135°C)

- Wear resistance and low friction coefficient

- NET Weight: 750 g

Fiberlogy Nylon PA12 Filament Description for 3D Printers

Discover engineering possibilities with Fiberlogy Nylon PA12 – a high-performance filament with a diameter of 1.75 mm and a weight of 750 g, available at the 3D4U store. This material, belonging to the polyamide (PA) family, is designed to create exceptionally strong, durable, and functional parts capable of withstanding harsh operating conditions.

Nylon PA12 from Fiberlogy features excellent mechanical strength, high wear resistance, and impressive flexibility (elongation at break over 200%). Its key advantages also include high heat resistance (up to 135°C) and exceptional resistance to a wide range of chemicals, including oils, hydraulic fluids, fuels, greases, salt water, and solvents. The material retains its properties even at sub-zero temperatures.

Thanks to these characteristics, Nylon PA12 has become an indispensable material in mechanical engineering, the automotive industry, and for the production of technical components. Finished products are easily machined with metalworking tools and can be painted, which expands their functionality. For even more demanding projects, Fiberlogy offers reinforced versions: PA12+CF15 (with carbon fiber) and PA12+GF15 (with glass fiber).

Important: Nylon PA12 is a hygroscopic material requiring thorough drying before printing. Due to its tendency to shrink, a 3D printer with an enclosed and heated chamber is necessary for successful printing.

3D4U is the official distributor of the Polish brand Fiberlogy products in Ukraine.

We offer a wide range of filament for 3D printing, including engineering materials, provide professional consultations, and guarantee the authenticity of all Fiberlogy products.

Fiberlogy Nylon PA12 Filament Properties

Fiberlogy Nylon PA12 possesses a unique set of properties making it an ideal choice for complex engineering tasks:

- High strength and durability: Ensures the reliability of parts under load.

- Exceptional flexibility: Elongation at break over 200%, allows for the creation of resilient elements.

- Excellent chemical resistance: Resistant to oils, fuels, hydraulic fluids, greases, salt water, and solvents (except concentrated alkalis and acids).

- High heat resistance: Heat Deflection Temperature up to 135°C (HDT @ 0.45 MPa).

- Wear resistance and low friction coefficient: Ideal for moving parts such as gears and slide bearings.

- Low-temperature resistance: Retains properties at temperatures below 0°C.

- Machinability and paintability: Allows for post-processing and customization of finished products.

- High impact strength: Parts are resistant to impact loads (12 kJ/m² Izod).

Drying is critical: Nylon actively absorbs moisture from the air. Undried filament will lead to printing defects (bubbles, poor layer adhesion, reduced strength). Dry at 70°C for at least 4 hours before each print.

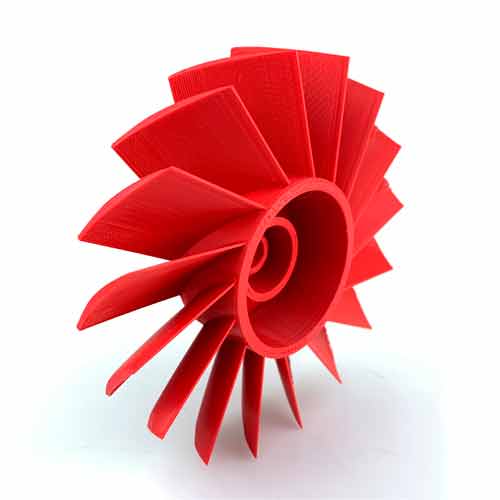

Fiberlogy Nylon PA12 Print Examples

Assess the strength and precision of parts printed with Fiberlogy Nylon PA12 filament:

Strong and lightweight drone frame made of Nylon PA12

Turbine impeller requiring strength and heat resistance

Wear-resistant gear made of Nylon PA12

Applications of Fiberlogy Nylon PA12

Thanks to its outstanding characteristics, Nylon PA12 is ideally suited for a wide range of engineering and technical applications:

- Mechanical components: Gears, cogs, guides, bushings, slide bearings, cams.

- Technical parts: Nuts, washers, latches, connecting elements, adapters.

- Automotive industry: Under-the-hood components, fuel connectors, interior parts, prototypes.

- Industrial equipment: Robot grippers, tooling, jigs, wear-resistant pads.

- Functional prototypes: Testing parts that require high strength, flexibility, and chemical resistance.

- Orthopedics and prosthetics: Elements of prostheses and orthoses (biocompatibility check required for specific application).

Fiberlogy Nylon PA12 Print Settings

Printing with nylon requires attention to detail. The following parameters are recommended for Fiberlogy Nylon PA12. Optimal settings may require adjustment for your specific 3D printer.

| Parameter | Value |

|---|---|

| Nozzle Temperature | 255-270°C |

| Bed Temperature | 90-110°C |

| Enclosed Chamber | Required (preferably heated) |

| Fan Speed | 0-10% (minimal or off) |

| Flow Rate | 95-105% |

| Printing Speed | 35-60 mm/s |

| Build Surface | Glass + PVA glue, Garolite, PA-specific build surfaces |

| Retraction (direct drive) | Yes, 2-3 mm |

| Retraction (bowden) | Yes, 4-6 mm (can be trickier due to flexibility) |

| Retraction Speed | 20-45 mm/s |

| Drying Conditions | 70°C / 4-12 hours (MANDATORY before printing) |

Key Points for Printing PA12:

1. Drying: Nylon is extremely hygroscopic. Printing without prior and thorough drying is impossible. Store filament in an airtight container with desiccant.

2. Enclosed Chamber: Necessary to maintain a stable high temperature and prevent warping and layer delamination due to shrinkage.

3. Bed Adhesion: PA12 adheres poorly to standard surfaces. Use PVA glue (diluted with water or as a stick), specific adhesives, or surfaces like Garolite (G10/G11).

Fiberlogy Nylon PA12 Technical Specifications

| Parameter | Value | Test Method |

|---|---|---|

| Diameter | 1.75 mm ± 0.02 mm | - |

| Average Roundness | + 0.01 mm | - |

| Specific Density | 1.01 g/cm³ | ISO 1183 |

| Tensile Strength @ Yield | 45 MPa | ISO 527 |

| Tensile Strength @ Break | 51 MPa | ISO 527 |

| Tensile Modulus | 1400 MPa | ISO 527 |

| Elongation @ Yield | 5% | ISO 527 |

| Elongation @ Break | >200% | ISO 527 |

| Flexural Strength | - (No data in TDS) | ISO 178 |

| Flexural Modulus | 1150 MPa | ISO 178 |

| Izod Impact Strength (Notched @ 23°C) | 12 kJ/m² | ISO 180 |

| Heat Distortion Temperature @ 0.45 MPa | 135°C | ISO 75 |

| Heat Distortion Temperature @ 1.8 MPa | 55°C | ISO 75 |

| Vicat Softening Temperature | 145°C | ISO 306 |

| Glass Transition Temperature (Tg) | - (No data in TDS) | DSC |

| Melting Temperature (Tm) | 178°C | DSC |

| Continuous Use Temperature (UL Yellow Card) | 65°C | UL 746 |

Tips for 3D Printing with Fiberlogy Nylon PA12

Printing Nylon PA12 requires preparation and attention, but the results are worth it. Here are key tips:

- Drying, Drying, and More Drying: This is the most crucial step. Dry the filament at 70°C for 4-12 hours (longer is better) before every print. Use a dedicated filament dryer or food dehydrator. Wet nylon will bubble, crackle, adhere poorly, and produce brittle parts.

- Airtight Storage: After drying, immediately place the spool in an airtight container with plenty of desiccant. It's best to print directly from a drybox.

- Enclosed and Warm Chamber: A stable temperature inside the chamber (ideally 50-70°C) is critical to prevent shrinkage, warping, and delamination.

- Bed Preparation: Use PVA glue (applied to a cold bed and dried), Garolite (G10/G11), or PA-specific coatings. A clean glass or PEI bed usually doesn't provide enough adhesion.

- Temperature Settings: Use high nozzle (255-270°C) and bed (90-110°C) temperatures as recommended.

- No Cooling Fan: Part cooling is detrimental as it causes rapid cooling and exacerbates shrinkage and layer adhesion issues. Set the fan speed to 0%.

- Print Speed: Don't print too fast. Start at 35-40 mm/s and gradually increase if quality allows. Slower printing improves layer bonding.

- Retraction: Tune retraction carefully to avoid clogs while minimizing stringing. Nylon can be prone to oozing.

Tip: Start by printing small test models (like a calibration cube) to fine-tune your drying, temperature, and adhesion settings before attempting large and complex projects.

Comparison of Fiberlogy Nylon PA12 with Other Engineering Materials

Nylon PA12 occupies its niche among engineering plastics. Here's how it compares to alternatives:

| Material | Key Advantages of PA12 | Key Disadvantages of PA12 | When to Choose PA12 |

|---|---|---|---|

| Fiberlogy PA12 | Excellent chemical resistance, high flexibility (>200%), wear resistance, good heat resistance (HDT 135°C), strength | High hygroscopicity (requires drying), difficult to print (needs chamber, special adhesion), moderate stiffness | For parts requiring flexibility, chemical resistance, wear resistance (gears, bearings), operating in harsh environments or low temperatures. |

| Fiberlogy PA12+CF/GF | Significantly higher stiffness and strength, higher heat resistance, dimensional stability | Lower flexibility, abrasive (requires hardened nozzle), higher cost, also hygroscopic | For rigid, strong parts under high load, where maximum performance is needed. |

| Fiberlogy ABS / ASA | Easier to print (less hygroscopic, better adhesion), higher stiffness, lower cost | Significantly lower chemical resistance, lower wear resistance, lower flexibility, lower heat resistance (esp. ASA under high load) | For enclosures, structural parts where extreme chemical or wear resistance isn't needed. ASA for outdoor use. |

| Fiberlogy Easy PET-G | Much easier to print, low hygroscopicity, good impact strength | Significantly lower heat resistance (~70°C), lower chemical resistance, lower wear resistance | For general-purpose functional parts where PLA isn't strong enough and ABS's heat resistance is overkill. |

| Other Nylons (e.g., PA6) | PA12 is less hygroscopic than PA6, more dimensionally stable in humidity, lower density | PA6 typically has higher strength and heat resistance | When dimensional stability in humid environments and better processability compared to PA6 are important. |

Fiberlogy Nylon PA12 is the choice for those needing a balance of strength, exceptional flexibility, chemical and wear resistance, and who are prepared to provide the necessary printing conditions.

Why Choose Fiberlogy Nylon PA12

Choosing Fiberlogy Nylon PA12 from 3D4U gives you access to a high-quality engineering material with several undeniable advantages:

- Engineering Grade: Material designed to solve complex technical challenges.

- Chemical Inertness: Resistance to a wide range of aggressive media, oils, and solvents.

- Mechanical Endurance: Combination of strength, impact resistance, and incredible flexibility.

- Wear Resistance: Ideal for creating durable friction pairs (gears, bearings).

- Thermal Stability: Ability to operate at elevated and low temperatures.

- Fiberlogy Quality: Guarantee of consistent filament diameter and material purity for predictable printing (when conditions are met).

- 3D4U Support: As an official distributor, we provide consultations and guarantee product authenticity.

Despite the higher demands of the printing process, Fiberlogy Nylon PA12 rewards the user with unique properties in finished products, unattainable with most other FDM materials.

How to Order Fiberlogy Nylon PA12

Ordering Fiberlogy Nylon PA12 filament in Ukraine is easy and fast through the 3D4U online store:

- Select the desired color and weight (750 g).

- Add the product to your cart using the "Buy" button.

- Go to the cart to review your order.

- Proceed to checkout, providing contact information and delivery details.

- Choose convenient payment and delivery methods within Ukraine.

- Confirm your order.

If you need help choosing an engineering plastic for your 3D printer or have questions about nylon printing settings, our specialists are ready to provide expert advice.

Realize your most ambitious engineering projects with Fiberlogy Nylon PA12!

FAQ (Frequently Asked Questions) about Fiberlogy Nylon PA12

Significantly more difficult. The main challenges are related to nylon's high hygroscopicity (requires mandatory and thorough drying before each print and storage in a dry place) and its tendency to warp (requires a 3D printer with an enclosed, preferably heated, chamber and special methods for bed adhesion). PLA and PETG are much less demanding regarding printing conditions and are more forgiving of errors.

Printing wet nylon will lead to numerous problems:

- Hissing and popping from the nozzle: Water vaporizing inside the filament.

- Bubbles and porosity: The part surface will be rough, with visible bubbles.

- Poor layer adhesion: The part will be brittle and easily delaminate.

- Stringing: Increased amount of thin strands between model parts.

- Inconsistent extrusion: Possible under-extrusion or even nozzle clogs.

- Reduced mechanical properties: Strength, flexibility, and other characteristics will be significantly worse than specified.

Essentially, quality printing with wet nylon is impossible.

Nylon PA12 adheres poorly to standard surfaces like clean glass or PEI. The most popular and effective solutions are:

- PVA glue: Regular white school glue (PVA glue stick) or a solution of PVA in water, applied thinly to the bed. Let it dry before printing.

- Garolite (G10/G11): A sheet material based on fiberglass composite, to which nylon adheres excellently. Often used as a removable build plate.

- Specialized adhesives: There are glues and coatings designed specifically for printing nylon (e.g., Magigoo PA).

- Perforated plate: Some users achieve success on perforated build plates.

Using a brim to increase the first layer contact area is also important.

Yes, Nylon PA12 is one of the best materials for printing gears and other moving parts due to its:

- High wear resistance: It withstands friction better than many other plastics.

- Low coefficient of friction: Ensures smooth sliding.

- Good strength and impact resistance: Withstands loads and impacts.

- Chemical resistance: Resistant to lubricants.

For maximum gear durability and strength, consider using reinforced nylons (PA12+CF or PA12+GF), but standard PA12 also shows excellent results.

PA12 and PA6 are two common types of nylon, but with different properties:

- Hygroscopicity: PA12 absorbs significantly less moisture than PA6. This makes PA12 more dimensionally stable in humid environments and slightly easier to dry and store (although both require drying).

- Mechanical Properties: PA6 is generally slightly stronger, stiffer, and has a higher melting point and heat resistance than PA12.

- Flexibility: PA12 is often more flexible and has better elongation at break.

- Density: PA12 has a lower density.

- Cost: PA12 is typically more expensive than PA6.

The choice between them depends on priorities: if maximum strength and heat resistance are more important - PA6; if dimensional stability in humid environments, flexibility, and lower hygroscopicity are key - PA12.

For printing pure Nylon PA12 (like this filament from Fiberlogy), a standard brass nozzle is suitable. PA12 itself is not an abrasive material.

However, if you plan to print reinforced nylons, such as PA12+CF (with carbon fiber) or PA12+GF (with glass fiber), then a wear-resistant nozzle is mandatory. Carbon and glass fibers are very abrasive and quickly wear out standard brass nozzles. For such materials, it is recommended to use nozzles made of hardened steel, coated stainless steel (e.g., Nozzle X), or with a ruby/sapphire tip.

| Manufacturer | Fiberlogy |

|---|---|

| Printing technology | FDM/FFF |

| Material type | PA12 |

| Printing temperature, ℃ | 250-270 |

| Platform temperature, ℃ | 100 |

| Filament diameter, mm | 1.75 |

| Allowable deviation, mm | ±0.02 |

| Density, kg/m³ | 1.01 |

| Color | Gray Silver |

| Surface Finish / Effect | Metallic / Metal Effect |

| Filler / Additives | No Additives |

| Heat Resistance | Engineering (Above 110°C) |

| Specific Resistance | Chemically Resistant Wear Resistant / Low Friction |

| Special Properties | Impact Resistant Rigid |

| Spool Format | Standard Spool |

| Length, m | 308 |

| Weight, kg | 0.750 |

| Country | Poland |

| Condition | New |

No reviews for the product