Ви нічого не додали до кошика

Перейти до категорії:

Ви нічого не додали до кошика

Перейти до категорії:

Завантажуючи 3D-модель, чи замислювалися ви про ліцензію? Дізнайтеся, як Creative Commons та інші ліцензії регулюють...

Відкрийте для себе Bambu Lab A1 Mini - 3D-принтер, який змінює правила гри у світі доступного 3D-друку. Дізнайтеся,...

Думаєте, що 3D-друк — це просто купівля принтера та пластику? Ми розкриємо всі приховані витрати та покажемо, як...

Революція в 3D-друку: Bambu Lab створює технології, що знижують вплив на довкілля на 80%, економлять до 20% пластику...

SILK пластик — це інноваційний матеріал для 3D-друку, який дозволяє створювати вироби з гладкою, блискучою поверхнею,...

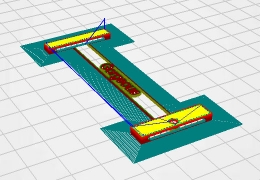

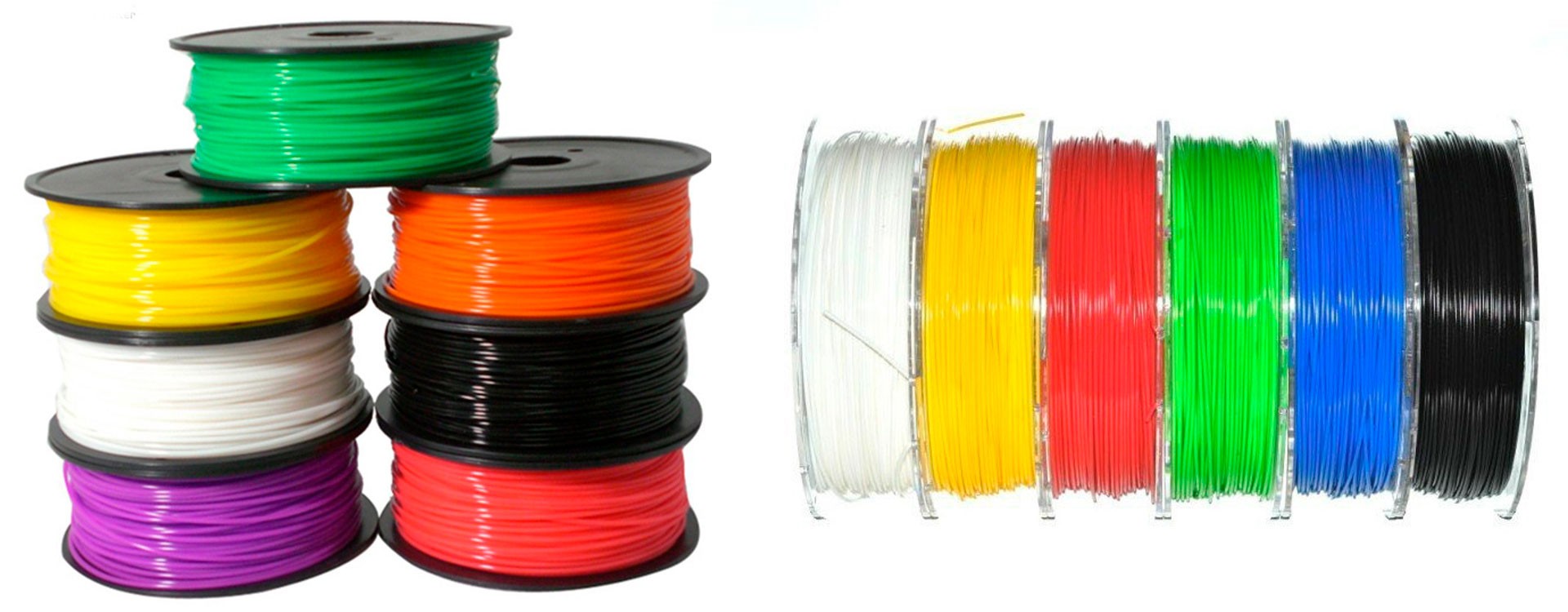

3D-друк відкрив нову еру у виробництві та прототипуванні, дозволяючи створювати складні об'єкти з неймовірною точністю та швидкістю. Ключовим елементом цієї технології є різні типи пластиків, кожен з яких має унікальні властивості та застосовується для вирішення специфічних завдань. У цій статті ми розглянемо основні види пластиків для 3D-друку, їхні характеристики та сфери застосування.

ABS — один з найпопулярніших матеріалів для 3D-друку, відомий своєю міцністю та стійкістю до ударів.

Характеристики ABS:

ABS ідеально підходить для виготовлення функціональних прототипів, деталей механізмів та корпусів електроніки. Його міцність і теплостійкість роблять його відмінним вибором для виробництва іграшок, автомобільних деталей та побутових предметів.

У нашому магазині ви можете знайти широкий вибір ABS пластику діаметром 1.75 мм різних кольорів для ваших проєктів.

PLA — біорозкладний пластик, який отримують з природних матеріалів. Він популярний завдяки простоті використання та екологічності.

Характеристики PLA:

PLA відмінно підходить для друку декоративних виробів, прототипів та моделей, які не потребують високої міцності або термостійкості. Його часто використовують в освітніх цілях та для створення сувенірної продукції.

Ознайомтеся з нашим асортиментом PLA пластику діаметром 1.75 мм, включаючи стандартні та спеціальні варіанти з ефектами металіку, глітеру та ті, що світяться у темряві.

PETG поєднує в собі найкращі якості ABS та PLA, пропонуючи хорошу міцність та простоту друку.

Характеристики PETG:

PETG часто використовується для виготовлення функціональних прототипів, харчових контейнерів та водонепроникних виробів. Його прозорість робить його відмінним вибором для створення візуально привабливих об'єктів.

Для ваших проєктів ми пропонуємо широкий вибір PETG пластику різних кольорів та відтінків.

TPU — еластичний матеріал, що забезпечує гнучкість та міцність надрукованих виробів.

Характеристики TPU:

TPU ідеально підходить для створення гнучких деталей, таких як чохли для телефонів, взуттєві підошви, ущільнювачі та захисні кожухи. Його здатність поглинати удари робить його відмінним вибором для захисних елементів.

Якщо вам потрібен гнучкий та міцний матеріал, зверніть увагу на наш асортимент TPU пластику.

Окрім основних типів пластиків, існує ряд спеціалізованих матеріалів, розроблених для конкретних застосувань:

Нейлон відрізняється високою міцністю, зносостійкістю та гнучкістю. Він ідеально підходить для створення функціональних деталей, що потребують довговічності та стійкості до механічних навантажень.

ASA схожий на ABS, але має кращу стійкість до ультрафіолетового випромінювання та погодних умов. Це робить його відмінним вибором для виробів, що використовуються на відкритому повітрі.

Для друку деталей, стійких до зовнішніх впливів, рекомендуємо звернути увагу на наш ASA пластик.

Полікарбонат відомий своєю високою міцністю та теплостійкістю. Він часто використовується в інженерних застосуваннях, де потрібна стійкість до високих температур та механічних навантажень.

HIPS часто використовується як підтримувальний матеріал у складних моделях, особливо в поєднанні з ABS, оскільки легко розчиняється в лімонені. Крім того, він має хорошу міцність і підходить для створення легких та недорогих моделей.

При виборі пластику для 3D-друку важливо враховувати наступні фактори:

Щоб допомогти вам зробити правильний вибір, ми підготували порівняльну таблицю основних типів пластиків:

| Тип пластику | Міцність | Гнучкість | Теплостійкість | Простота друку | Постобробка |

|---|---|---|---|---|---|

| ABS | Висока | Середня | Висока | Середня | Відмінна |

| PLA | Середня | Низька | Низька | Висока | Хороша |

| PETG | Висока | Середня | Середня | Висока | Середня |

| TPU | Середня | Дуже висока | ВИсока | Висока | Обмежена |

Важливо: Перед початком друку завжди перевіряйте сумісність обраного пластику з вашим 3D-принтером. Деякі матеріали можуть вимагати спеціальних налаштувань або модифікацій обладнання для досягнення оптимальних результатів.

Різноманітність пластиків для 3D-друку відкриває широкі можливості для реалізації найсміливіших ідей та проєктів. Від міцного ABS до гнучкого TPU, кожен матеріал має свої унікальні властивості та сфери застосування. Вибір правильного пластику може значно вплинути на якість, міцність та функціональність вашого кінцевого виробу.

Незалежно від того, чи створюєте ви прототип нового продукту, друкуєте функціональні деталі або експериментуєте з декоративними об'єктами, розуміння характеристик різних пластиків допоможе вам досягти найкращих результатів у ваших 3D-друкованих проєктах.

Якщо ви тільки починаєте свій шлях у світі 3D-друку або хочете розширити свої можливості, рекомендуємо ознайомитися з нашим асортиментом 3D-принтерів. Ми пропонуємо широкий вибір моделей, прикладних як для новачків, так і для досвідчених користувачів.

Для тих, хто хоче експериментувати з різними матеріалами, наш каталог пластиків для 3D-друку пропонує широкий вибір філаментів різних типів та кольорів.

Не забувайте, що правильний вибір пластику — це лише початок. Для досягнення найкращих результатів важливо також освоїти техніку 3D-друку, налаштування слайсера та постобробку виробів. Продовжуйте експериментувати, вчитися та створювати дивовижні речі за допомогою 3D-друку!

Ліцензії 3D-моделей (Creative Commons та інші): Що можна і не можна друкувати/продавати?

Ліцензії 3D-моделей (Creative Commons та інші): Що можна і не можна друкувати/продавати?

Bambu Lab A1 Mini: Прорив у світі доступних 3D-принтерів

Bambu Lab A1 Mini: Прорив у світі доступних 3D-принтерів

Скільки насправді коштує 3D-друк: аналіз усіх витрат

Скільки насправді коштує 3D-друк: аналіз усіх витрат

Зелена революція в 3D-друку: як Bambu Lab змінює індустрію

Зелена революція в 3D-друку: як Bambu Lab змінює індустрію

SILK пластик для 3D-друку: створення ефектних моделей

SILK пластик для 3D-друку: створення ефектних моделей

Додати товар в список бажань, щоб купити його пізніше або поділитися ним з друзями